Information dynamic

资讯动态

辉锐凭借近二十年激光熔覆技术经验,为海外客户定制专用设备,通过优化机械结构与工艺,提升涂层质量与生产效率。设备采用模块化设计,便于安装,核心部件包括激光器、送粉器、水冷机等,具备电压自适应、创新水冷、灵活气体保护及智能控制等功能,确保熔覆质量稳定、操作简便。

此外,辉锐提供一站式服务,涵盖简化安装、云端监控、全流程培训及售后支持,帮助客户快速投入使用。公司已为全球多个行业提供定制化解决方案,广泛应用于石油化工、工程机械等领域,未来将继续聚焦技术创新,满足多样化需求,推动行业发展。

螺杆等工业零部件在长时间运行后,表面难免会出现不同程度的磨损和腐蚀。这些状况会导致螺杆表面尺寸失准,无法与料筒正常匹配进行挤压作业,进而严重影响挤出效率和质量。

After long-term operation, industrial components such as screws are inevitably subject to wear and corrosion on the surfaces. These conditions would cause inaccuracies in the surface dimensions of the screws, preventing them from properly matching with the barrel for extrusion operations, and thereby severely affecting extrusion efficiency and quality.

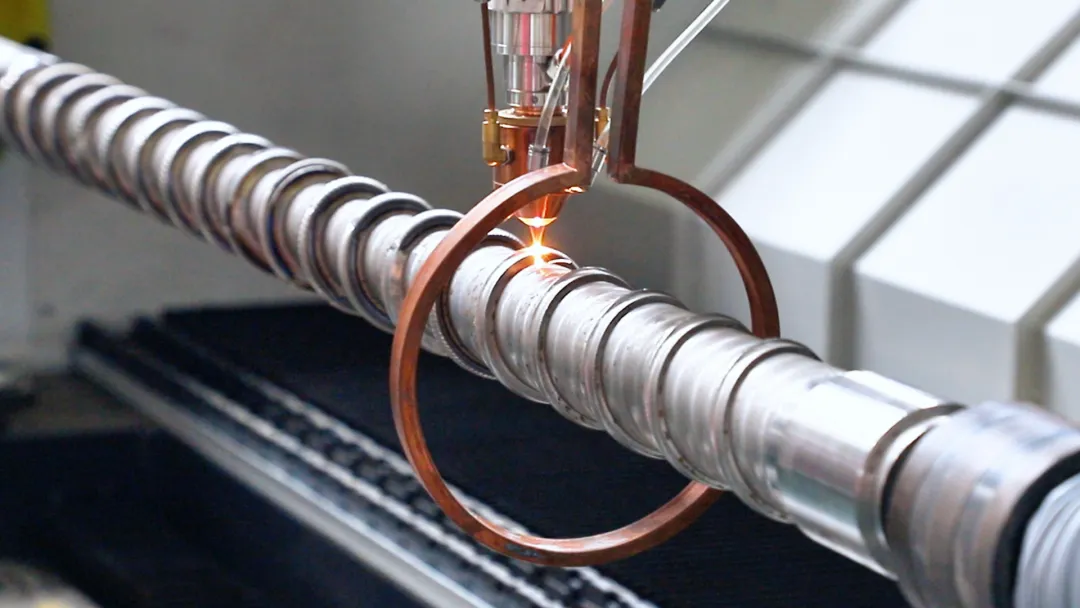

在传统的螺杆修复或强化工艺中,电镀、热喷涂、堆焊等技术存在诸多弊端。例如,热输入量过高易引发螺杆变形,基材热影响区域过大,且涂层表面硬度难以满足实际使用要求。而激光熔覆技术则能有效解决上述难题,经该技术加工后的螺杆,性能甚至优于全新产品,不仅直接降低了零部件成本,还缩短了交货周期,显著提高了综合效益。

In traditional repair or strengthening processes for screws, techniques such as electroplating, thermal spraying, and surfacing welding come with numerous drawbacks. For instance, excessive heat inputting would cause deformation of the screws, with overly large heat-affected zones in the base material. Moreover, it is difficult for the surface hardness of the coatings to meet actual usage requirements. In contrast, laser cladding can effectively address these challenges. Screws processed by this technology exhibit superior performance of new products. This not only directly reduces the cost of components but also shortens delivery lead times, significantly enhancing overall cost-effectiveness.

辉锐:近二十年技术沉淀,助力客户解决难题

Huirui: With nearly two decades of technological accumulation, we help clients solve their challenges

辉锐在激光熔覆增材制造领域拥有近二十年的经验与技术积累,凭借深厚的技术底蕴,已成功帮助国内众多客户解决了大量螺杆表面涂层强化难题。此次,针对某海外螺杆领域客户对工件表面强化的迫切需求,辉锐技术团队展现出了卓越的专业能力。

Huirui has nearly two decades of experience and technological accumulation in the field of laser cladding additive manufacturing. Leveraging its profound technological expertise, the company has successfully assisted numerous domestic clients in solving a multitude of challenges related to screw surface coating reinforcement. On this occasion, in response to the urgent demand for workpiece surface strengthening from an overseas client in the screw industry, Huirui's technical team demonstrated outstanding professional competence.

辉锐技术团队精准洞察并深度理解了海外客户的技术要求,从加工精度、效率到工艺稳定性等各个方面进行了深入分析与优化。同时,紧密结合设备在实际应用场景中的特点,包括具体的使用场景以及电压环境差异,为客户量身定制了高性能的螺杆激光熔覆专用设备,有效提升了客户的生产效能与产品质量。

The Huirui technical team accurately perceived and thoroughly comprehended the technical requirements of the overseas client. They conducted in-depth analysis and optimization across various aspects, ranging from processing accuracy and efficiency to process stability. Meanwhile, by closely integrating the characteristics of the equipment in real-world application scenarios, including specific usage conditions and differences in voltage standard, they tailored a high-performance dedicated laser cladding equipment for screws.

螺杆激光熔覆设备介绍

Introduction to Screw Rod Laser Cladding Equipment

螺杆激光熔覆设备:量身定制,高效优质

Huirui Screw Laser Cladding Specialized Equipment: Customized to Order, Ensuring High Efficiency and Superior Quality

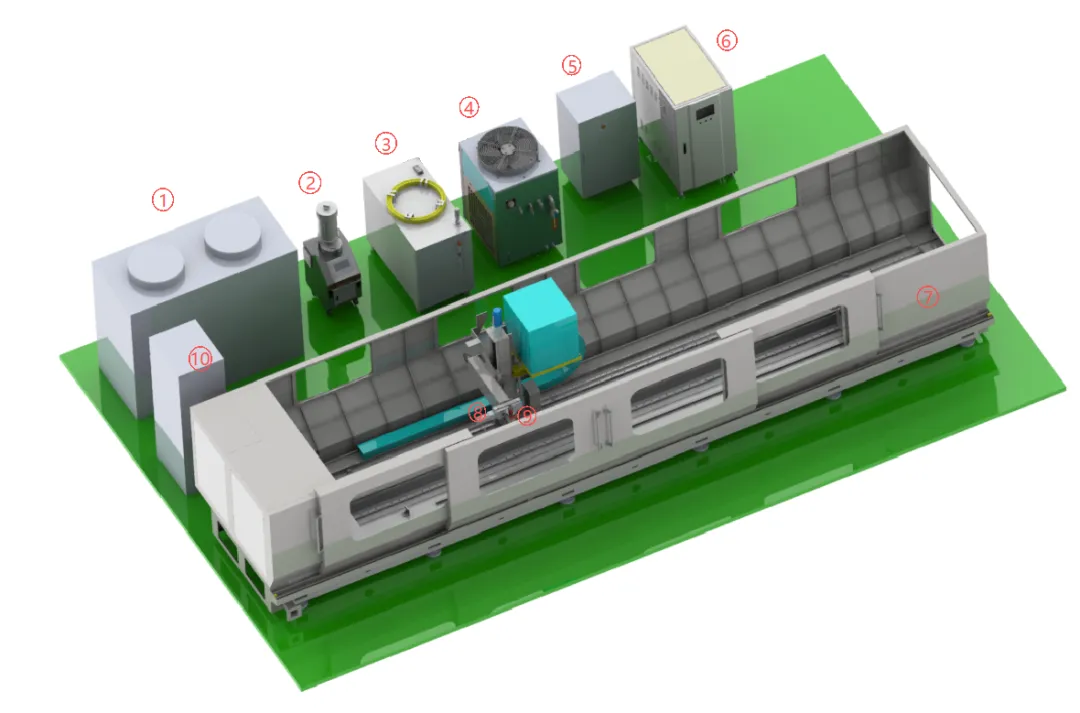

该设备是辉锐根据螺杆行业客户需求专门量身定制的激光熔覆专用设备。通过一系列机械结构调整以及工艺优化,大幅提高了螺杆表面涂层强化质量及生产效率。设备整体采用模块化集成设计,便于海外客户快速安装调试。其外观设计精致合理,不仅操作性和可靠性更高,还能有效减少金属粉末外溢,更好地保护生产环境。设备主要包含以下核心部分:

This equipment is a specialized laser cladding machine tailored by Huirui to meet the specific needs of customers in the screw industry. Through a series of mechanical structure adjustments and process optimizations, it has significantly enhanced the quality of surface coating reinforcement and production efficiency for screws. The entire equipment features a modular integrated design, facilitating rapid installation and commissioning for overseas customers. Its exquisitely designed and reasonably structured appearance not only ensures higher operability and reliability but also effectively minimizes metal powder spillage, thereby better protecting the production environment. The equipment primarily comprises the following core components:

1. 感应加热水冷机、2.送粉器、3.激光器、4.水冷机5.电控柜、6.稳压电源、7.转台、8.摆动器、9.激光头10.感应加热电源

1.Chiller of Induction Heater、2.Powder Feeder、3.Laser Source、4.Chiller of Laser、5.Control Cabinet、6.Regulated Power Supply、7.Rotator、8.Oscillator、9.Laser Head 10.Induction Heater Power Supply

设备参数

Equipment Parameters

设备优势显著,满足多元需求

The equipment has significant advantages and meets diverse needs

电压自适应能力强:设备安装了高精度调压器,能够为激光器与转台提供稳定电源。当电网电压出现瞬时波动时,能在极短时间内将输出电压稳定在±2%以内,有效避免了因电压不稳导致的设备停机、熔覆质量偏差等问题,确保生产连续稳定。

Strong voltage self-adaptation capability: The equipment is equipped with a high-precision voltage regulator that can provide a stable power supply for both the laser and the rotary table. When instantaneous fluctuations occur in the grid voltage, it can stabilize the output voltage within ±2% in an extremely short time. This effectively avoids issues such as equipment shutdown and deviations in cladding quality caused by unstable voltage, thereby ensuring continuous and stable production.

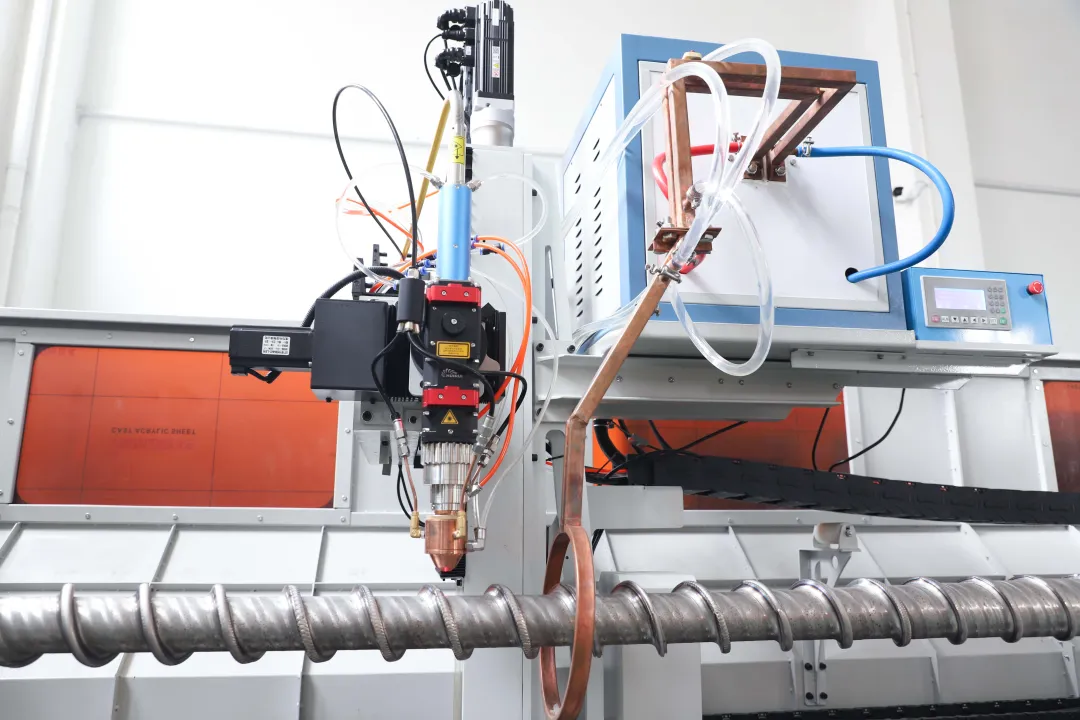

创新水冷设计:激光熔覆头水冷部分采用储水贯穿整体的循环冷却方式,冷却面积大、散热效率高,能快速带走熔覆头工作热量。同时,大幅简化了进出水管线布局,使管线连接更简洁,后期维护拆卸、安装更方便,降低了海外客户的设备维护成本与难度。

Innovative water-cooling design: The water-cooling section of the laser cladding head adopts a circulating cooling method where water is stored and flows through the entire structure. This design offers a large cooling area and high heat dissipation efficiency, enabling swiftly remove the heat during the operation of the cladding head. Meanwhile, it significantly simplifies the layout of the inlet and outlet water pipelines, making the pipeline connections more concise. This facilitates easier disassembly and installation during subsequent maintenance, thereby reducing the equipment maintenance costs and difficulties for overseas customers.

灵活气体保护:设备支持氮气、氩气等多种惰性辅助气体回路选择,客户可根据熔覆材质与工艺需求灵活切换。气体系统内置控制阀与流量显示功能,通过电气控制实现惰性气体精准供应,避免了人工调节误差,稳定保障了熔覆质量。

Flexible gas shielding: The equipment supports the selection of multiple inert auxiliary gas circuits, such as nitrogen and argon, allowing customers to flexibly switch based on the cladding material and process requirements. The gas system is equipped with built-in control valves and flow display functions, enabling precise supply of inert gases through electrical control. This eliminates manual adjustment errors and steadily ensures high-quality cladding results.

双重保障熔覆质量与效率:采用同轴送粉方式,粉末与保护气体同步输送,气流由内向外吹扫,有效防止了光学透镜污染,减少了粉尘排放,延长了光学部件使用寿命,保障了熔覆层均匀优质。

Dual assurance for cladding quality and efficiency: The coaxial powder feeding method is employed, where powder and shielding gas are delivered simultaneously. The gas flow, sweeping from the inside out, effectively prevents contamination of the optical lenses, reduces dust emissions, extends the service life of optical components, and ensures uniform and high-quality cladding layers.

智能控制,操作简便:配备四轴联动控制系统,采用直线导轨、齿轮齿条与滚珠丝杠结构,支持手动/自动模式切换,集成温度传感器,支持实时在线温度检测,实现工件加热和保温功能,确保工艺稳定性,且操作人员可快速上手,简化了操作门槛。

Intelligent Control with Simple Operation: Equipped with a four-axis coordinated control system, it utilizes linear guide rails, rack-and-pinion mechanisms, and ball screw structures. The system supports seamless switching between manual and automatic modes, and integrates temperature sensors for real-time online temperature monitoring. It enables functions for heating and holding workpieces at constant temperatures, ensuring process stability. Additionally, operators can quickly master its use, significantly lowering the operational skill threshold.

核心部件全部自制,彰显硬实力

All core components are self-manufactured, showcasing our strong technical capabilities

辉锐自主研发的核心部件——激光熔覆头与送粉器,展现了强大的技术实力。激光熔覆头在原版基础上进行了全方位的升级优化,重量减轻了25%,冷却效率提升了30%,支持直板型、过渡型光路切换,能够满足复杂曲面加工的需求。单桶送粉器采用步进电机为转盘提供动力,转速稳定可控,专门用于高精度激光加工送粉,送粉精度误差≦1%,适用于热喷涂、激光熔覆、3D打印、半导体非金属粉末输送等应用。

The core components independently developed by Huirui—the laser cladding head and powder feeder—demonstrate its formidable technical prowess. The laser cladding head has undergone comprehensive upgrades and optimizations based on the original version, resulting in a 25% reduction in weight and a 30% improvement in cooling efficiency. It supports switching between flat-plate and transitional optical paths, enabling it to meet the demands of complex curved surface machining. The single-hopper powder feeder utilizes a stepper motor to drive the rotating disc, ensuring stable and controllable rotational speeds. Specifically designed for high-precision laser processing powder feeding, it achieves a powder feeding accuracy error of ≤1%, making it suitable for applications such as thermal spraying, laser cladding, 3D printing, and semiconductor non-metallic powder delivery.

辉锐“一站式无忧服务”:全方位保障

HuiRui's "One-Stop Hassle-Free Service": Comprehensive Guarantee

1.简化安装流程

Simplified Installation Process

设备内置了惰性气体安装接口,客户现场仅需连接气源即可启用,省去了跨国运输压力容器的繁琐流程,为客户节省了时间和成本。

The equipment is equipped with built-in inert gas installation interfaces, allowing customers to simply connect a gas source on-site to activate the system. This eliminates the cumbersome process of transporting pressurized containers across borders, saving customers both time and costs.

2.云端监控与在线支持

Cloud-Based Monitoring and Online Support

通过云端监控系统,辉锐可以实时诊断设备状态。同时,配备的7×24小时在线工程师团队能够快速响应海外客户的运维需求,确保设备始终处于良好的运行状态。

Through a cloud-based monitoring system, Huirui can diagnose equipment status in real-time. Additionally, our 7×24-hour online engineering team can swiftly respond to the operational and maintenance needs of overseas customers, ensuring that the equipment always operates in optimal condition.

3.全流程培训流程

Full-Process Training Services

辉锐的技术团队为客户提供操作、维护、激光工艺全流程培训,确保客户人员能够独立掌握设备使用技能,降低后期运营成本。

Huirui's technical team provides comprehensive training course covering operation, maintenance, and laser processing techniques. This ensures the customer can independently master equipment usage skills, thereby reducing long-term operational costs.

赋能海外工业在制造:定制化服务持续发力

Empowering Overseas Industrial Remanufacturing: Customized Services Continue to Deliver Strong Performance

此次螺杆激光熔覆专用设备的定制交付,不仅是辉锐技术实力的又一次有力验证,更是辉锐“以客户需求为核心”服务理念的生动体现。从项目前期与海外客户的深度沟通,全面了解当地电压标准、生产场景、熔覆工件特性等需求,到项目中期的方案设计、技术创新与设备制造,再到项目后期的安装指导、操作培训与售后支持,辉锐全程提供“一站式”定制化服务,确保设备能快速适配客户生产流程,实现“开箱即用”。

The customized delivery of this dedicated screw laser cladding equipment not only serves as another robust validation of Huirui's technological prowess but also vividly embodies its service philosophy of "placing customer needs at the core." From in-depth preliminary communication with overseas clients to fully grasp their local voltage standards, production scenarios, and characteristics of cladding workpieces, to mid-project stages encompassing solution design, technological innovation, and equipment manufacturing, and extending to post-project phases including installation guidance, operational training, and after-sales support, Huirui provides a comprehensive "one-stop" customized service throughout the entire process. This ensures that the equipment can swiftly adapt to the client's production workflow, achieving "plug-and-play" functionality right out of the box.

截至目前,辉锐已为全球众多国家和地区的客户提供了众多量身定制的成套设备解决方案,这些设备广泛应用于石油化工、工程机械、电力能源等领域的表面强化与再制造。针对批量化激光熔覆修复特殊应用场景,辉锐已成功开发出玻璃模具冲头、截齿、刹车片、刀模、轴内外径一体等系列激光熔覆专机,切实帮助企业大幅节省了设备成本。

Up to now, Huirui has provided numerous tailored complete equipment solutions to customers in many countries and regions around the globe. These equipment solutions are widely applied in surface strengthening and remanufacturing across industries such as petrochemicals, engineering machinery, and power energy. In response to special application scenarios involving batch laser cladding repairs, Huirui has successfully developed a series of dedicated laser cladding machines, including those for glass mold punches, cutting picks, brake pads, die cutters, and integrated inner and outer diameter shafts. These machines have effectively helped enterprises significantly reduce equipment costs.

展望未来,辉锐将始终秉持技术创新理念,以全球化服务为坚实后盾,精准聚焦不同国家、不同行业客户的个性化需求,全力打造更高效、更稳定、更智能的激光熔覆解决方案,引领行业迈向新高度。

Looking ahead to the future, Huirui will always uphold the philosophy of technological innovation, with globalized services as a solid foundation. We will precisely focus on the personalized needs of customers from different countries and industries, striving to create more efficient, stable, and intelligent laser cladding solutions, and leading the industry to new heights.

咨询服务:025-8675 6108

售后服务:025-8675 6109

总部地址:南京市江宁区瑞鑫路1号智能

制造创新产业园

苏公网安备 32011302320467号

苏公网安备 32011302320467号

业务咨询热线:025-8675 6108 售后服务热线:025-8675 6109

总部地址:江苏省南京市江宁区瑞鑫路1号智能制造创新产业园内